See what you’re missing

What are your parts telling you?

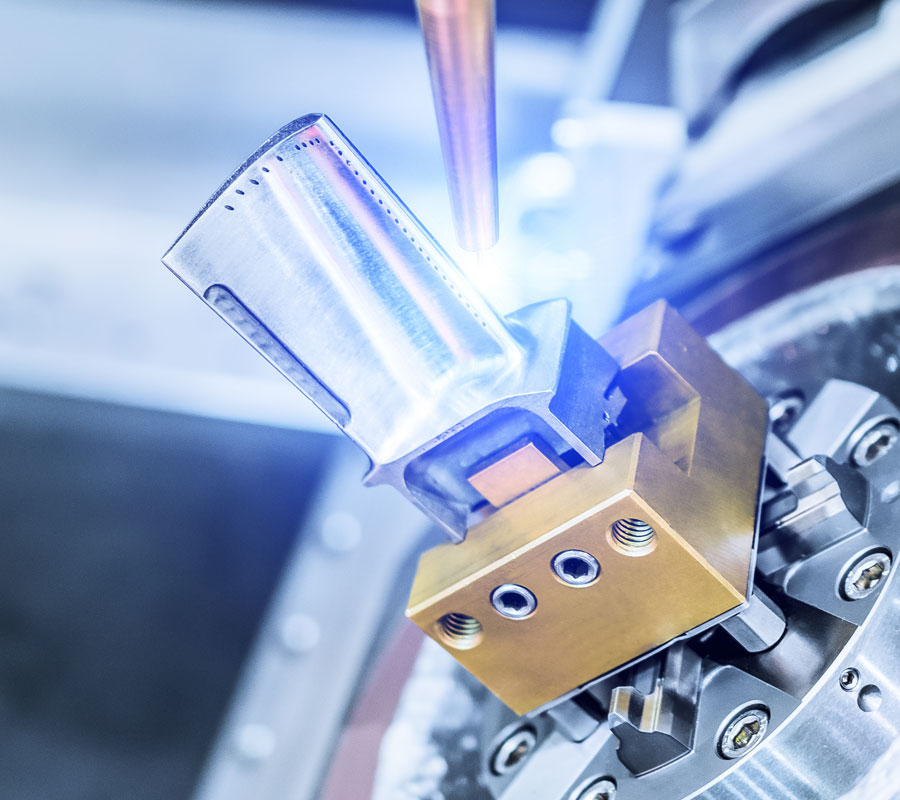

Traditional aerospace NDT methods inspect only for known issues and in many cases only testing a small fraction of the parts due to sampling practices. Destructive testing quickly becomes costly. Adding Vibrant’s revolutionary PCRT testing to your NDT inspection routine allows you to quickly test all parts to immediately identify every potential issue and end costly destructive testing.

The Wholistic Approach

Unlike standard NDT, which can many hours for a single part, Vibrant tests parts in a matter of seconds, comparing data from the whole part against all others. Comparative analysis quickly identifies parts out of conformity, even on microstructural and chemical levels.

Aerospace Applications

More than any other industry, each part in aerospace is mission critical. A single defect has the potential for costly or even catastrophic consequences. Resonance delivers a whole-body view of every part, giving you the power to better identify and eliminate defects well before failure on a large variety of aerospace parts, regardless of metal, alloy or material composition.

Advanced Materials

Vibrant’s PCRT successfully tests all standard aerospace metals and alloys as well as a number of advanced materials.

- Equiax, directionally-solidified and single crystal superalloys

- Ceramics

- Composites

Processes

PCRT technology supports parts manufactured under a large variety of processes.

- Casting

- Forging

- Welding

- Additive manufacturing

- Induction hardening

- Hot isostatic pressing (HIP)

- Composite fabrication processes

- Ceramic matrix composite (CMC) fabrication processes

Airframe Components

Ensure critical components don’t become the weakest link.

- Fasteners

- Control system mechanisms (gears, linkages)

- Structural components

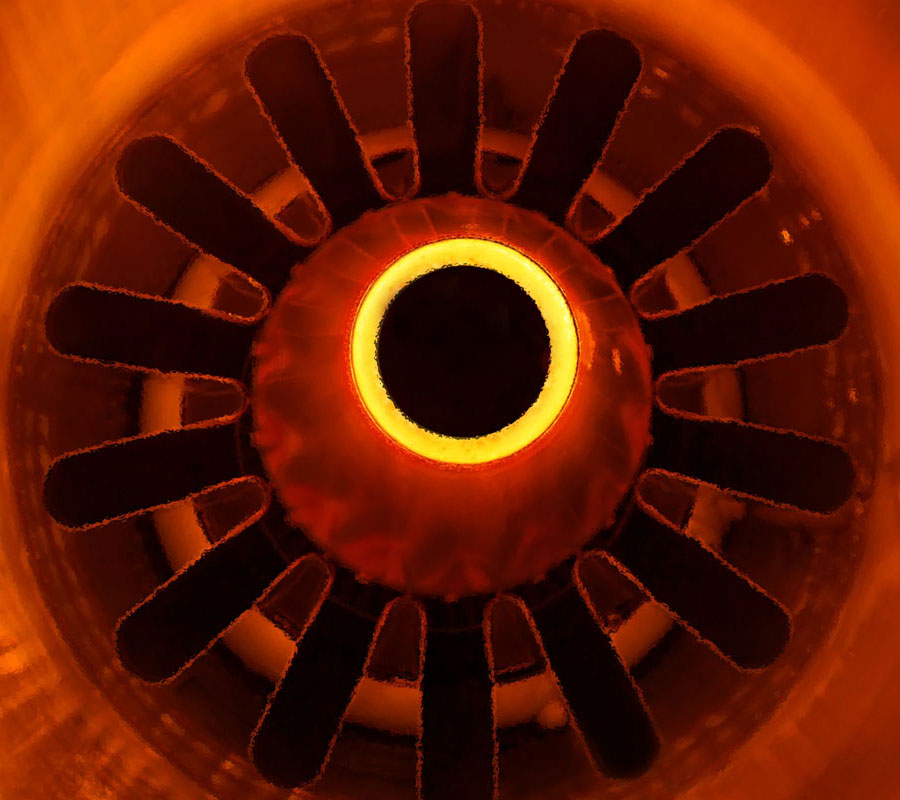

Aircraft Engines

Vibrant’s PCRT testing technology rapidly tests critical parts vital to engine health and life.

- Turbine blades, nozzles, and disks

- Fuel nozzles

- Impellers

- Shafts

- Hybrid bearing ceramic rolling elements

- Static components (shrouds, endwalls)

- Radial turbines

Landing Gear

Exposed to some of the highest stress on an aircraft, landing gear and components are highly susceptible to potential failure.

- Wheels

- Carbon brake disks

- Torque tubes

- Structural and kinematic components (pistons, sleeves, trunions)

- HVOF-coated components

- Fasteners

- Bolts

Discover how PCRT Technology can help you

Learn more about how Vibrant can reduce your costs and risk in the aerospace industry with our advanced resonance testing.