Aircraft wheels are vital components that undergo regular inspections to ensure their structural integrity and performance. Traditionally, inspections required costly and time-consuming preparation methods like stripping and repainting. With the advent of advanced technology, Vibrant’s revolutionary inspection technique, known as Process Compensated Resonance Testing (PCRT), has emerged as a game-changer in the industry. In just under a year, nearly 20,000 aircraft wheels have undergone PCRT inspections.

In this blog, we will explore how PCRT has revolutionized the inspection process, particularly its transition from inspecting used parts to now also inspecting new parts. This shift allows for comprehensive comparisons between new and used components, offering valuable insights for maintenance, repair, and overhaul (MRO) practices.

PCRT Part-to-Itself Inspections

One of the significant advantages of PCRT in wheel MRO is the ability to perform part-to-itself inspections (PTI). PTI involves comparing a component’s current state to its baseline measurements taken earlier, enabling precise analysis of any changes or degradation over time. For aircraft wheels, which undergo frequent inspections, PTI inspections prove highly beneficial due to their faster payback and increased efficiency.

PTI measurements of 3 different wheels at a standard maintenance interval. The most recent measurement of wheel A shows a significant change due to rejectable damage to the wheel. The repeat measurements of wheels B and C show very little change – structural integrity is maintained.

The Limitations of Traditional Inspection Standards

Prior to PCRT, aircraft wheel inspections primarily relied on Fluorescent Penetrant Inspection (FPI), a method that involved stripping and repainting the wheels. This process was not only expensive and time-consuming but also prone to errors and inconsistent results. PCRT has emerged as a superior alternative, offering significant advantages over traditional inspection techniques.

Quantitative Analysis of Wheel Changes

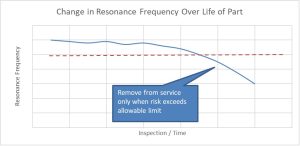

Inspection intervals for aircraft wheels are often set conservatively to ensure safety. However, such conservative intervals may lead to unnecessary maintenance and associated costs. PCRT allows for a quantitative analysis of wheel changes over time, enabling a more precise understanding of their condition. By assessing the actual state of the wheels, maintenance intervals can be optimized, reducing unnecessary maintenance actions while maintaining safety.

Birth Certificate Measurements for New Parts

To further enhance the inspection process, Vibrant recently installed a PCRT system at the Collins New Manufacturing facility in Troy, Ohio. This system enables the acquisition of birth certificate measurements for new wheels. These measurements serve as a baseline reference for future inspections, allowing for comprehensive comparisons between the initial condition of the wheel and its subsequent state during service.

Expanding Risk Protection in an Uncertain Supply Chain

PCRT of new parts not only benefits the individual manufacturer but also offers an added layer of risk protection in an uncertain supply chain. By using PCRT to inspect new components, manufacturers can identify forging defects, detect missed machining or other process operations, and evaluate the consistency of suppliers over time. This comprehensive inspection approach ensures the highest quality standards and mitigates potential risks associated with the supply chain.

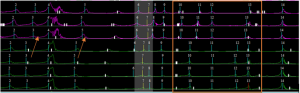

This photo showcases two suppliers: the top three items belong to one supplier, while the bottom four belong to a different supplier. Within each group, the resonance spacing (left-right) remains consistent, but there are noticeable spacing changes between the colored groups, especially in the 10-11-12-13 range. These differences can be attributed to variations in dimensions, material properties, and stress states.

The integration of PCRT in the aircraft wheel inspection process marks a significant advancement in MRO practices. By shifting the focus from inspecting only used parts to also inspecting new components, PCRT allows for comprehensive comparisons, optimizing maintenance intervals, and ensuring enhanced safety. The ability to perform part-to-itself inspections and the acquisition of birth certificate measurements offer a new level of precision and risk protection in an industry that demands the utmost reliability and performance. As PCRT continues to evolve, its impact on the aerospace industry will undoubtedly shape the future of wheel inspection practices.

Learn more about PCRT for Aircraft Wheels here.