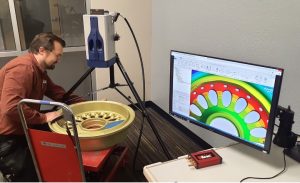

At Vibrant, we’re always on the lookout for cutting-edge technologies that can enhance our services and benefit our customers. Recently, we took a significant step by acquiring a state-of-the-art Polytec vibrometer. In this blog post, we’ll delve into what this powerful instrument is and how it’s poised to make a difference in our ability to serve our customers, especially when used in conjunction with our existing PCRT technology.

What is a Vibrometer?

A vibrometer represents a specialized and highly precise instrument designed for the quantification and analysis of vibrations within mechanical structures and components. Much like a medical professional employs a stethoscope to listen to the intricacies of a patient’s heartbeat, the vibrometer, similar to PCRT in this context, serves as a diagnostic tool that discerns the subtlest vibrations and resonances emanating from various mechanical components and materials – similarly to PCRT.

This highly sophisticated device operates on the principle of optical interferometry. It detects minute details in the optical path length, allowing it to accurately capture and quantify displacements, accelerations, and velocities of vibrational phenomena. The precision and reliability of a vibrometer are important for an in-depth examination of a component’s structural integrity, offering our customers a comprehensive view of their mechanical systems.

Seeing the Resonance Difference

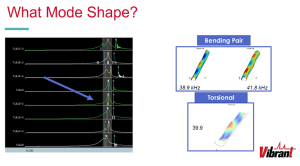

While Vibrometry is slower than PCRT alone, the key advantage of the vibrometer (for Vibrant) is its ability to visualize the shape of the components’ resonances. This is a game-changer for our customers. In addition to our numerical data, we can now see the mode shapes associated with each resonance peak. This not only allows for more precise analysis but also validates our understanding of how a component behaves under varying conditions.

Enhancing Process Control and Quality Assurance, Hand in Hand with PCRT

For our customers, the acquisition of the vibrometer translates to enhanced process control and quality assurance. Vibrometry is highly useful for evaluating and supporting non-contact measurement methods, and it complements PCRT seamlessly. This ensures that our diagnostic resonances target the areas of your parts that are most critical. PCRT continues to be an integral part of our service, and the vibrometer further enhances the capabilities of our comprehensive testing solutions.

By incorporating these new tools into our PCRT workflow, we can improve the accuracy of our models and digital twins. These models are crucial for predicting the complex behavior of components under different conditions, and lead to safer and more efficient operations.

Expanding the Scope of PCRT and Vibrometry

The vibrometer is not just about improving current processes; it also allows us to expand the use of PCRT to new applications, providing enhanced versatility in our testing capabilities. For our customers, this means more flexibility in how we can serve you. The potential to explore new applications and serve a wider range of industries is an exciting prospect.

Vibrant’s journey with the vibrometer has just begun, and we’re already seeing its significant impact alongside our trusted PCRT technology. As we move forward, we’ll continue to explore the full range of capabilities this instrument offers when paired with PCRT and how it can be leveraged to benefit our customers.

We’re committed to maintaining our position at the forefront of NDT and always strive to deliver the best services possible to our customers. The vibrometer, in conjunction with PCRT, is another step in our ongoing quest for excellence.

Keep an eye on this space as we share more updates on our journey with the vibrometer and its integration with PCRT. We’re excited to continue exploring the possibilities it offers and how it can drive innovation in the world of NDT, always with our customers‘ needs in mind.