Process Compensated Resonance Testing (PCRT) requires precision and sensitivity. As technology advances and industries evolve, the demands placed on PCRT testing have grown increasingly complex. From its origins in high-volume automotive production to its expanded applications in aerospace and additive manufacturing, the journey of fixturing in PCRT testing reflects a continuous quest for innovation and adaptability. In this blog, we delve into the transformative journey of fixturing in PCRT testing, exploring its evolution and the challenges it addresses across diverse industries.

Adaptation to Changing Demands:

Two decades ago, PCRT testing primarily catered to the high-volume demands of the automotive industry. With thousands of identical parts produced daily, the focus was on quick test times and efficient throughput. Frequently, applications required multiple copies of the same test fixture to meet these volume requirements. Because of the sensitivity of the PCRT measurement, each fixture had to be identical, to enable data collected on each to be interpreted in exactly the same way (or to produce a common pass/fail result or compare to a common reference set).

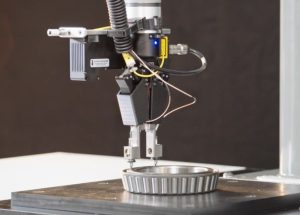

Examples of older versions of fixtures – each is customized to a single specific part number/design.

Transition to Aerospace and Lower Volumes:

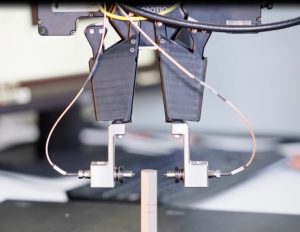

In contrast, the aerospace industry operates with lower volumes. To fully utilize the test capacity of PCRT systems in this sector, fixtures needed to evolve to support testing of multiple part numbers. The requirement for fixture repeatability remains and becomes even more important if the inspection is focused on comparing a part to itself over time. Variation from fixture-fixture cannot interfere with detection of changes in the part due to accumulation of damage. The development of robotic REX platforms provided the necessary repeatability and flexibility to handle diverse part streams, enabling effective testing across a wide range of components.

Learn more about REX by clicking here

Examples of new fixtures that move to the part via a robotic arm, and can adjust the specific locations where transducers are placed.

Versatility in Additive Manufacturing:

The rise of additive manufacturing introduced new challenges and opportunities for PCRT testing. As customers embraced the flexibility of this manufacturing method, the need for adaptable testing solutions became apparent. Robotic cells equipped with vision systems to find a part located anywhere in the test area, or to locate trays/arrays of parts that may be loaded onto a test deck, allow side-by-side inspection of parts produced through additive manufacturing, enhancing quality control and defect detection.

Targeted Inspection Approaches:

Ongoing projects are exploring innovative ways to leverage REX approaches for targeted inspections. While PCRT traditionally offers whole-body inspection capabilities, there’s growing interest in focusing on specific parts within a component. By combining insights from vibrometry or modeling with the reach of REX platforms, manufacturers can tailor resonance inspections to isolate signals relevant to individual parts of the whole, minimizing noise and maximizing detection accuracy.

The evolution of fixturing in PCRT testing reflects Vibrant’s commitment to optimizing efficiency, flexibility, and precision. From addressing high-volume demands in automotive to accommodating diverse part streams in aerospace and additive manufacturing, innovative fixture designs have revolutionized the way PCRT is applied across industries. As we continue to push the boundaries of inspection technology, watch for new systems that offer targeted inspection approaches, further enhancing the capabilities of PCRT testing.